Alison Miles of NIVUS.

Engineers engaged on a venture in North Wales have employed novel methods to enhance wastewater remedy effectivity, reportedly at a fraction of the price of conventional strategies, saving an estimated £3.5 million. Alison Miles from NIVUS, an instrumentation companion within the venture, explains the circulate measurement expertise behind the reported enhancements.

BackgroundOwned and operated by Dŵr Cymru Welsh Water, 5 Fords WwTW is a sewage works close to Wrexham in north-east Wales serving over 130,000 folks. The positioning operates three ASP (activated sludge course of) lanes.

As a Capital Supply Companion and a part of the Welsh Water Alliance, Mott MacDonald Bentley (MMB) was challenged to extend the remedy capability of the ASP lanes in response to a rising inhabitants and elevated demand from new anaerobic digestion vegetation.

The challengeThe present format of the plant delivered wastewater to the ASP lanes at a distinct circulate charge in every lane. This disparity was mirrored by dissolved oxygen measurements throughout the lanes, which indicated that the lanes weren’t working effectively. “One of the lanes, for example, was operating in a super-critical condition, whilst another was sub-critical,” explains MMB’s Jack Jones. “As a consequence, from a process control perspective, the ASP lanes were difficult to manage effectively.”

The uneven distribution of circulate between the ASP lanes was brought on by numerous bodily points within the circulate channels that fed them. As well as, a big 800mm aid pipe discharged a combination of RAS (returned activated sludge) and overspill instantly into the primary influx channel, which additionally affected the circulate profile.

The ASP lanes have been initially constructed with flumes to regulate circulate, however these have been changed with weirs to extend capability. The requirement for an additional improve in capability due to this fact meant {that a} return to flumes wouldn’t be practicable, and wouldn’t resolve the circulate disparity in any case.

A circulate break up chamber with equal weirs was additionally not thought of to be practicable as a result of this might trigger disruption to the operation of the plant, requiring important momentary works and civil prices. The ASP lanes can obtain as much as 1200 l/s in full circulate, so a weir-based answer would necessitate the rent of momentary pumps in the course of the development, which might be round 4 months, representing a considerable further price. This different was due to this fact disregarded.

Along with resolving the circulate disparity within the ASP lanes, it could be crucial to watch circulate within the aid pipe. This additionally represented a really important potential price, as a result of conventional methods corresponding to electromagnetic flowmeters usually require a full pipe for correct measurements and contain substantial set up prices and course of downtime. A latest trial evaluating the NIVUS insertion probe with a standard ‘magflow meter’ demonstrated a 60% saving in price and 95% saving in embodied carbon. The magflow possibility was due to this fact additionally disregarded.

The popular answer concerned the deployment of three actuated penstocks that might be lifted into the primary three channels.

The answer“Before making the final decision, a number of internal ‘surgeries’ were conducted involving hydraulic, mechanical and process engineers,” explains Josh Sparks, MMB Contracts Supervisor & EICA Regional Apply Lead. “As a company, we are always looking for innovative solutions that over-deliver on a number of fronts, and that is exactly what we managed to achieve at Five Fords.”

The popular answer concerned the deployment of three actuated penstocks that might be lifted into the primary three channels. The fourth channel can be remoted, however might be made accessible if crucial, sooner or later. Efficient management of the penstocks would rely closely on the dependable measurement of circulate in every channel downstream of the penstocks. “This was also a major challenge,” Josh explains. “Most traditional flow measurement methods were ruled out due to the physical constraints of the site, along with the cost of solutions involving significant civil works. As a result, we engaged with NIVUS and determined that their cross-correlation flow meters offered the best solution.”

NIVUS was contracted to put in circulate meters within the aid pipe, in the primary inlet channel, and in every of the three ASP inlet lanes. All of those devices are MCERTS and EX-rated and make use of the NIVUS cross-correlation circulate measurement methodology.

Two NIVUS POA wedge sensors have been fitted to L-shaped bed-mounted brackets – one on both aspect of the primary inlet channel. These sensors have been related to a (NF750 M9) transmitter, to which the pipe insertion probe (velocity profiler and ultrasonic stage) was additionally related.

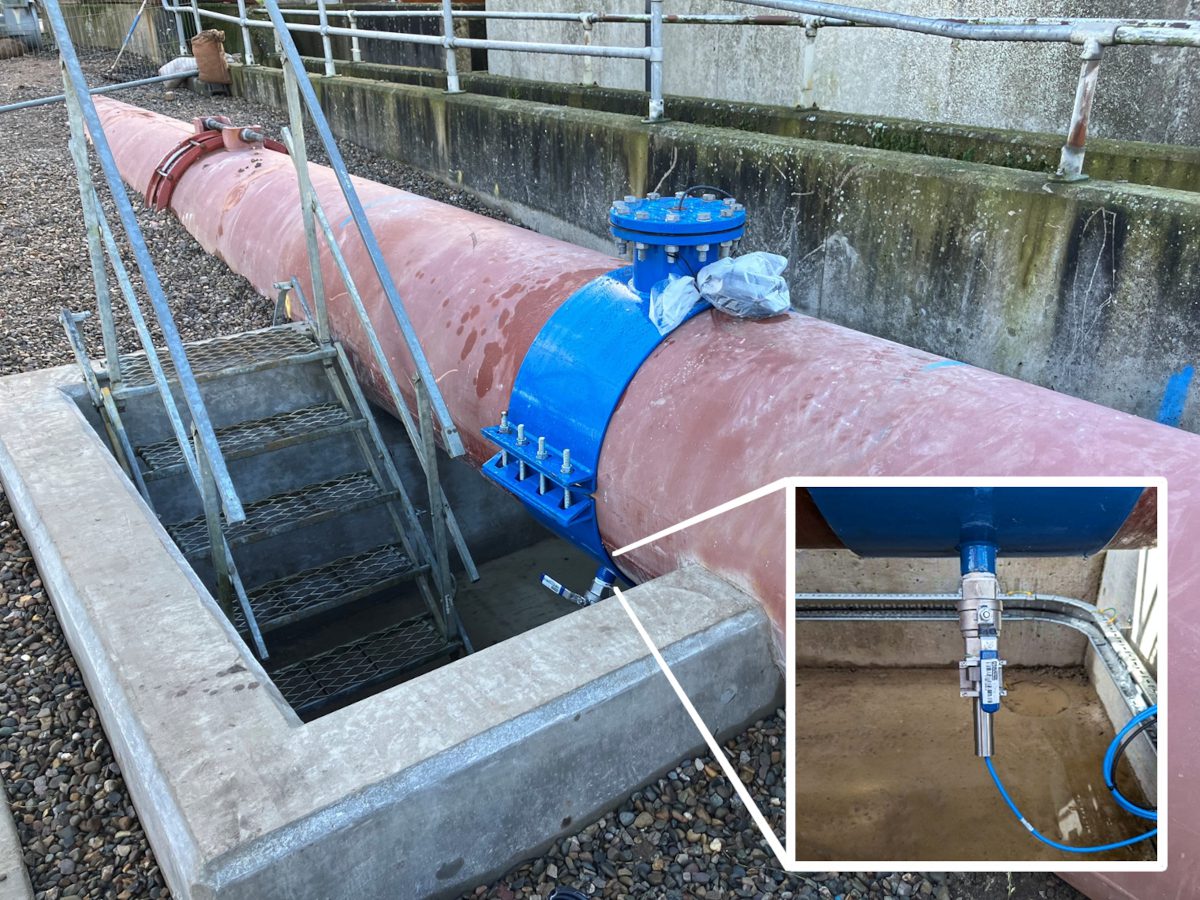

Circumferential strap with ‘top hat’ stage & Nivus insertion probe inset

Circumferential strap with ‘top hat’ stage & Nivus insertion probe inset

Every of the ASP lanes was fitted with a radar stage sensor, working along with POA wedge sensors, which have been additionally mounted on L-shaped bed-mounted brackets. Every of those sensors was related to a single enter transmitter (NF750).

Cross correlation circulate measurement methodThe ultrasonic cross-correlation methodology developed by NIVUS measures particular person velocities constantly at totally different ranges throughout the circulate. This space velocity circulate measurement approach offers a third-dimensional circulate profile that’s calculated in real-time to offer reproducible and verifiable circulate values in full or partially stuffed channels or pipes.

Nivus NF750 transmitter in IP68 subject enclosure.

Nivus NF750 transmitter in IP68 subject enclosure.

The strategy relies on the precept of ultrasonic reflection, through which reflectors corresponding to particles, minerals or gasoline bubbles throughout the water physique are scanned utilizing an ultrasonic impulse with an outlined angle. The ensuing echoes are saved as photographs or echo patterns, and an additional scan is carried out a number of milliseconds later. This creates echo patterns that are in contrast with beforehand saved alerts, and the positions of unambiguously identifiable reflectors are recognized so as to decide velocity, through the use of the beam angle. Which means that the particle velocity, which is equal to the wastewater circulate velocity, will be calculated from the temporal shift of the reflectors. The strategy produces extremely correct readings with out the necessity to carry out further calibration measurements.

A key benefit of this methodology is its capacity to function successfully in essentially the most demanding and closely polluted functions. Influencing components corresponding to flume form, discharge behaviour and wall roughness are all accommodated throughout the circulate computation.

Preliminary resultsThe NIVUS flowmeters have been put in earlier than the penstock answer was carried out, in order that circulate variation might be noticed each earlier than and after the penstock set up. Nonetheless, native engineers raised considerations in regards to the potential for the penstocks going from totally open to a closed place too shortly or not opening shortly sufficient throughout a surge, inflicting backup within the channel. As well as, there have been considerations that the penstocks would possibly react too shortly inflicting intermittently variable circulate charges.

Nivus sensor on sliding metal bracket.

Nivus sensor on sliding metal bracket.

“Happily, none of the initial concerns materialised,” Josh explains. “With the ability to optimise the ‘nudge and wait’ period, it became possible to ensure a smooth flow with an even split between the ASP lanes. As a result, the scheme sailed through the 28-day proving phase with no issues reported, and has performed problem-free for several months since that time.”

Key scheme outcomesThe total goal of the scheme was to equalise circulate charges throughout the three ASP lanes in order that remedy effectivity and capability can be improved. This was achieved, however as Josh says: “The penstock control system worked extremely well. By adopting a scheme based on cross-correlation flow measurement for both the relief pipe and the ASP channels, we were able to avoid substantial civil works, which delivered dramatic financial cost and carbon savings, as well as almost no interruption to the operation of the plant.”

MMB has estimated {that a} typical construct answer involving modification of the channels with a brand new distribution chamber would have taken round 8 months and value in extra of £4.5 million. In stark distinction, MMB’s answer, outlined above, was delivered at a price of round £1 million.

As a Capital Supply Companion and a part of the Welsh Water Alliance, beneath the phrases of its contract, MMB’s price financial savings at 5 Fords ship monetary advantages to each MMB and Dŵr Cymru Welsh Water. Consequently, the water firm’s clients additionally profit.

Trying forwardMMB employees have been so impressed with the outcomes of this venture that they’ve since organised inner webinars with engineering colleagues from all around the world, explaining how they can also implement this expertise to ship price and sustainability advantages.

The NIVUS cross-correlation circulate measurement expertise will probably be rolled out to future wastewater tasks. Nonetheless, it is usually relevant to different functions corresponding to pump administration beneath AMP8, in addition to in-pipe potable water circulate measurement functions.

Summarising, Josh Sparks says: “The physical constraints at Five Fords forced us to widen our search for potential solutions, and we have obviously been delighted with the results. Cross-correlation flow measurement turned out to be the key that unlocked the financial, time and carbon savings that have been achieved, and we look forward to delivering similar benefits on future projects.”

—-

Author : tech365

Publish date : 2025-01-22 17:55:02

Copyright for syndicated content belongs to the linked Source.